Single Ply (Membrane)

Single-ply membrane roofing, is a roofing system that incorporates wide rolls of either rubber or synthetic blends that are melded together to create a protective membrane for your building’s roof. There are two main types of single-ply systems: EPDM (Ethylene Propylene Diene Terpolymer) and TPO (Thermoplastic Polyolefin).

EPDM roofs have been used on industrial roofs for over 65 years, commonly known as “Black Roofs” for their colour. They offer excellent heat retention and elasticity, making them more popular in colder climate regions.

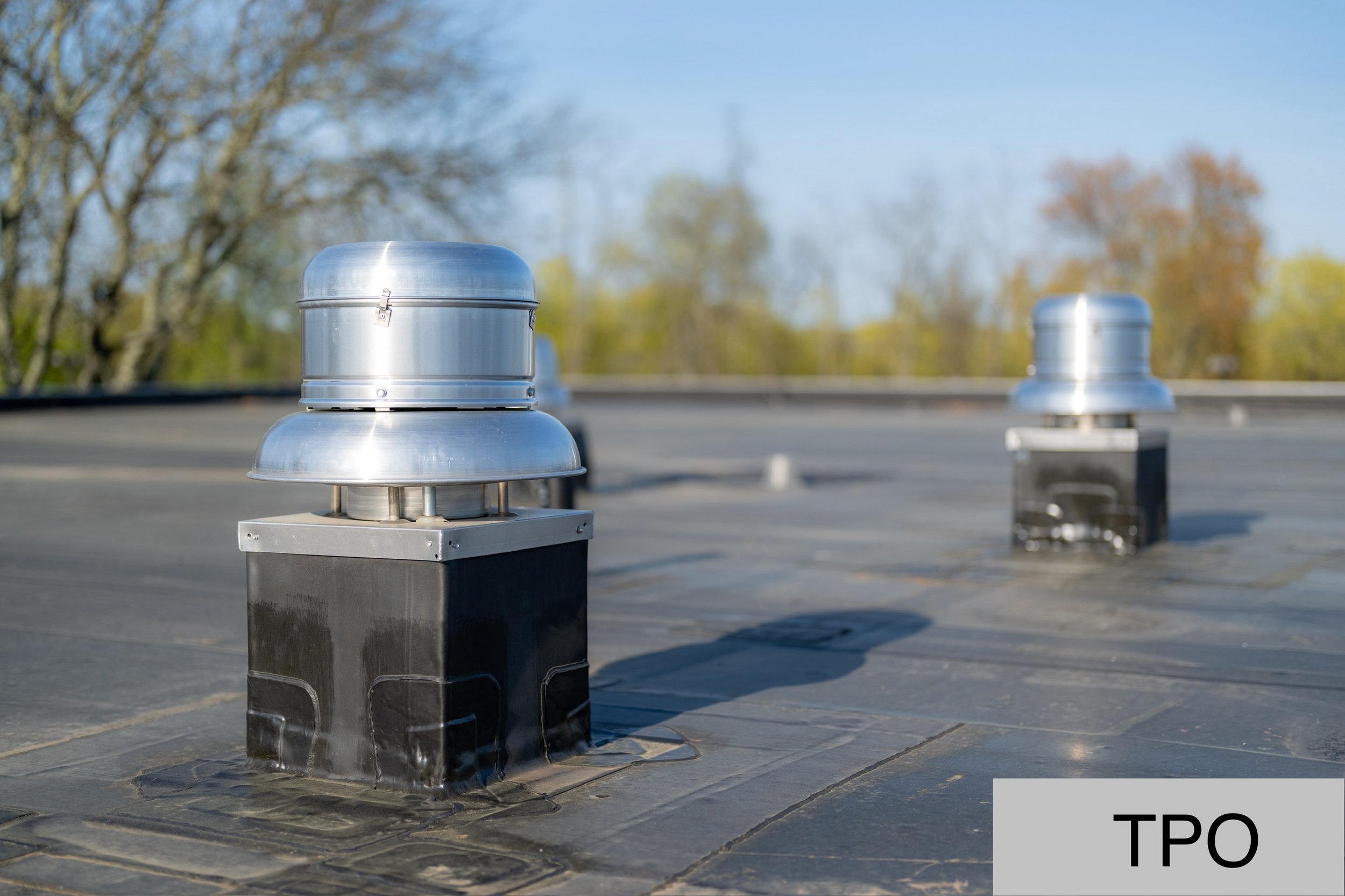

TPO roofs, are commonly known for their white roofs (Although available in other colours) - making them the choice for “Green Roofs” as the highly, heat reflective option. Although the newer of the two systems (In use for about 20 years), it is rapidly gaining popularity, particularly in warmer climate regions.

Although relatively cheaper in cost and easier to install, unlike Built-Up-Roofing (BUR) systems, they do not have a protective top layer. Due to this, they are much more susceptible to punctures and therefore leaks. Manufacturers do offer varying levels of membrane thickness, that also affect the length of warranties offered. Also, due to the nature of commercial/ industrial roofs, with its many accessories in the forms of vents, HVAC units, plumbing, sky lights… etc., the membrane rolls need to be cut into smaller pieces around these items. This further compromises the integrity of membrane (single-ply) roofs, along with its nature of the seam-sealing adhesive installation process as well as the degrading effect of UV rays on said adhesives. Due to this, single-ply membrane roofs may be more susceptible to leaks than other systems.